Also available in a mobile version

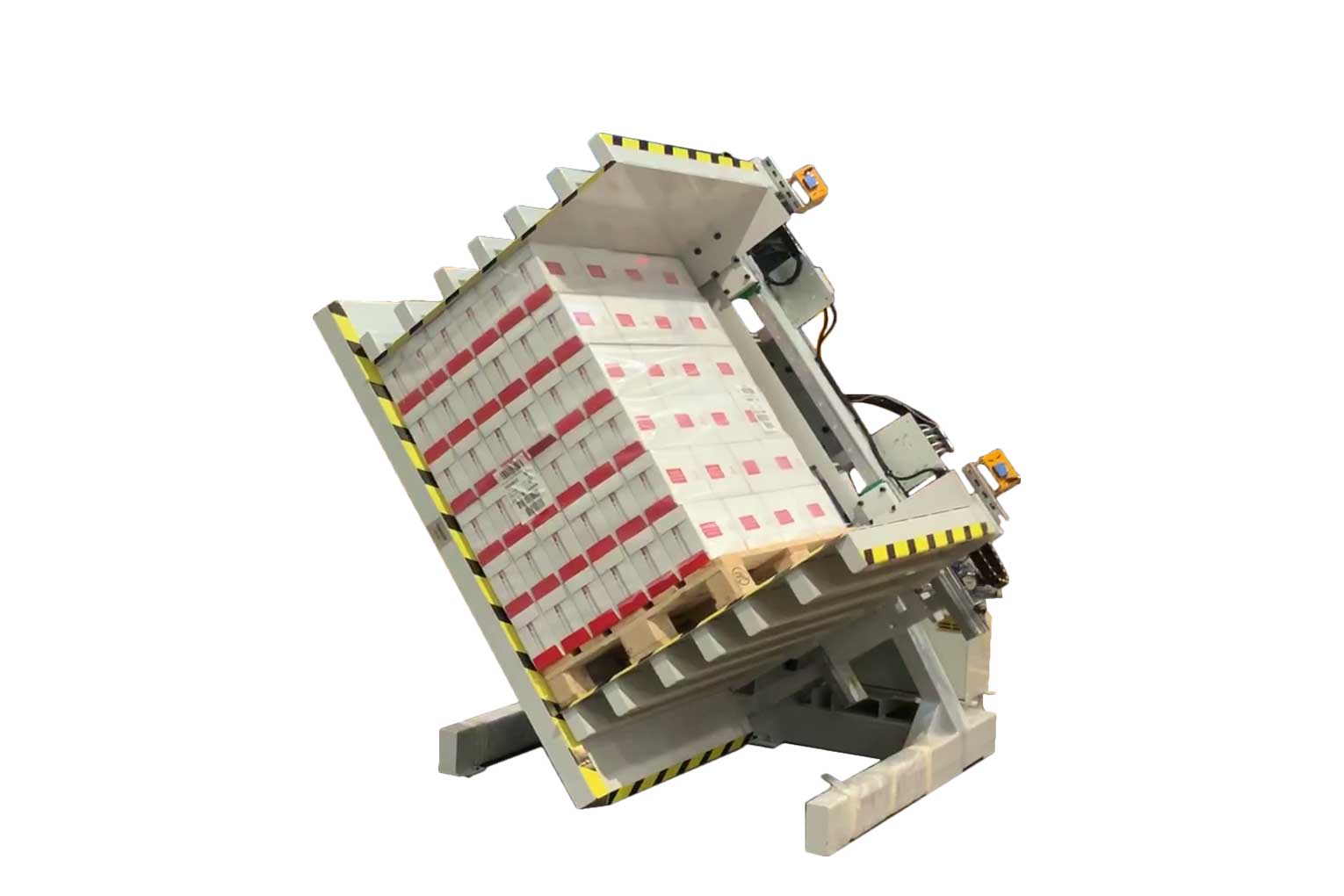

Pallet Flipper

A tried-and-true remedy is Toppy’s Classic Pallet Flipper. Introducing the Advanced Fixed Pallet Inverter, the model for 2023!

Semi-automatic system;

Easily rotate approximately 35 pallets per hour

Load capacity of up to 3300 lbs

Images for Fixed Pallet Flipper

Pallet Flipper Cycle Description:

This cutting-edge solution is a member of our family of pallet inverters.

The following stages are included in the pallet inverting process:

1- To put the pallet onto the machine, use a forklift.

2- Use a mobile platform to secure the weight from the top.

3- Rotate the whole load 180 degrees, which will raise the pallet above the load.

4- Reducing the platform will make room between the fixed platform and the inverted load.

5- If a new pallet is required, do so, or replace any damaged goods starting at the bottom.

6- Lift the platform to once again secure the weight.

7- To put the load back in its original place, turn it 180 degrees.

8- Disconnect the load from the mobile platform.

9- Arrange or fill the pallet.

A 90° turn option is provided for items that are less stable.

Your Safety is Our Top Priority

At Toppy America, efficiency and safety are both given high priority. Our inverter has crucial security components including safety photocells, metal perimeter defence, and fence nets. These characteristics make sure that operators can do duties safely. You can rely on us for safe and effective pallet handling.