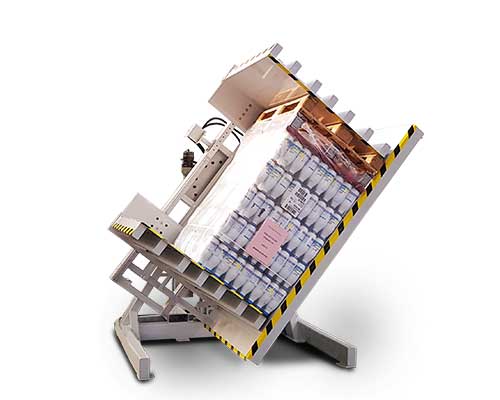

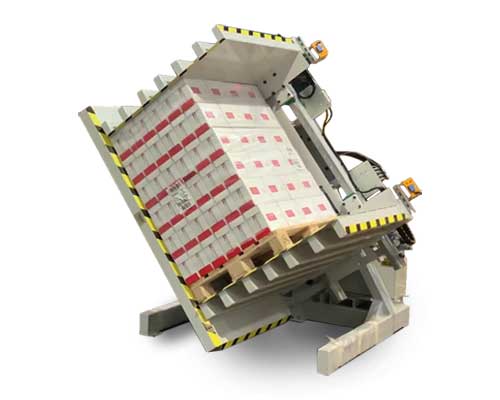

Pallet Rotator

“Ground Level”

Introducing the Toppy-original “Classic Ground Level” pallet turner. Check out the updated model of this device, introduced in 2023.

Enables the exchange of 35 pallets per hour;

Loading and unloading at ground level;

Capable of handling loads up to 3300 lbs

Images for Pallet Rotator

The “Classic Ground Level” pallet turner functions by turning the whole pallet load 180 degrees, making it simple for the operator to switch out pallets. Time is saved and labour in warehouses is decreased by this effective procedure.

- The pallet containing the cargo is manually or automatically lowered onto the lower level.

- During flipping, two extra platforms keep the product from moving.

- To enable pallet swapping once they are on top, the load is flipped 180 degrees.

- Following a pallet swap, the whole cargo is rotated 180 degrees and placed in its original location with a new pallet.

- A forklift operator then takes control and releases the goods for loading or stacking on the ground level.

What is a Pallet Turner?

Pallets may be turned or flipped using a pallet turner, a kind of material handling equipment. A pallet is automatically rotated 180 degrees to provide access to and management of the items on the other side. For a variety of sectors, including manufacturing, warehousing, and distribution centres, Top sectors provides cutting-edge pallet inverter solutions.

Study up on our “Classic Ground Level” here:

The “Classic Ground Level” can hold products with weights of up to 3300 lbs and lengths of 79 inches or shorter, handling practically all load types. It allows loading and unloading at ground level, making it simple to operate.

Benefits of Using a Pallet Turner:

There are several benefits for organisations using a pallet turner. A major advantage of automation is an increase in production due to less human handling and faster material movement. Through automation, there is less chance for accidents and product damage.

Automating the Process of Material Handling:

Pallet turner automation increases productivity and efficiency in the material handling process. Pallet turners from Toppy America are perfect for large-scale material handling requirements since they can handle a lot of pallets each hour. By automating the process, workers are freed up to work on other projects, increasing productivity and lowering expenses.

Customizable Pallet turner Solutions:

Toppy America is aware that every company has different requirements for material handling. Because of this, we provide solutions for pallet inverters that may be customised to meet your unique needs. Our specialists will collaborate with you to create a pallet turner that perfectly fits into your current workflow, increasing productivity and efficiency.

A Patented Pallet Inverter Machine with Versatility:

For hundreds of businesses looking for the finest pallet handling solutions, Toppy America is the ideal option. Our freezer spacer handling machine is a well-liked tool that helps cold storage and warehousing operations increase production with the least amount of labour. Find out whether it meets your demands by investigating its characteristics.

Pallet Turner Safety Features:

When it comes to material handling equipment, safety should always come first. The pallet turners made by Toppy America come with safety guards, overload protection, emergency stop buttons, and other security features. The safety of your workers and your goods is ensured by these measures, which reduce accidents and injuries.

Pallet Turner Maintenance

To keep pallet turners operating at their best and to extend their lifespan, regular maintenance is necessary. For your pallet exchangers, Toppy America provides maintenance services like as regular maintenance, repairs, and upgrades. You can minimise downtime and increase the lifespan of your pallet inverters with regular maintenance.

Selecting the ideal pallet turner for your company

Think about things like the size and weight of the items you handle when choosing a pallet exchanger. Choose a pallet turner model that can support your load since different versions have different weight capabilities. Also take into account the kind of material handling procedures used in your plant. Inline pallet turners can exchange around 100 pallets every hour without help from workers, making them ideal for automated procedures.

When choosing a pallet turner, it’s important to take into account the area that is available. A movable pallet inverter is adaptable for small spaces, while a fixed one is a reliable option for large spaces.

Benefits of the pallet turners from Toppy America:

- Greater efficiency and productivity: Our pallet rotators, also called pallet upenders, can handle a lot of pallets per hour, minimising human handling and enhancing material flow.

- Improved safety features: Our pallet turners include emergency stop buttons, overload protection, safety guards, and other measures.

- Customizable options: To fulfil your unique material handling requirements, we provide pallet turner options that are manufactured to order.

- reliable performance: Our pallet turners are constructed with high-quality materials and long-lasting components for reliable operation.

- Expert support: To ensure your pallet turner performs at its best and lasts as long as possible, our team of specialists offers maintenance, repairs, and updates.