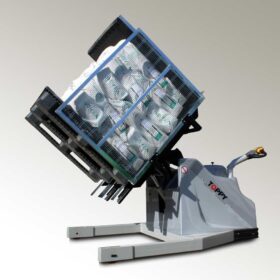

Portable Pallet Inverter

“Maxi Toppy”

Introducing the “Maxi Toppy” the first portable pallet inverter with a 20-pallet/hour capacity. By securely tipping the load, this small and adaptable solution revolutionizes pallet changeover and eliminates the need for physical labor.

Flexibility is enhanced by its portability;

Handle loads weighing up to 3300 pounds;

Easy operation with button panel & controller;

Efficiently change up to 20 pallets per hour;

Images for Pallet Inverter

“Maxi Toppy” is a portable pallet inverter

The “Maxi Toppy” is an electric-powered portale pallet inverter that is a member of our family of pallet inverters and is intended for weights up to 3300 lbs. It has an intuitive control panel and a gel battery for effective pallet tipping operations. It is appropriate for all sizes of warehouses due to its mobility.

The “Maxi Toppy” removes the need for specialised pallet-changing areas, making it ideal for small and constrained facilities. On a single charge, the gel battery can operate for a whole day. For unique customer needs, we can provide upgraded models with bigger batteries. For continuous operation, the roll-on/roll-off function automates cycle repetition.

Handling delicate goods? Visit our Pallet Changers page!

Although the “Maxi Toppy” is very efficient, fragile items may be vulnerable to harm when being inverted. Our sideways pallet changer systems provide an appropriate solution in these situations. Reach out to us to discuss the best pallet handling alternatives for your particular need.

Cycle of portable pallet inverter

Pallets are switched out for fresh ones by load overturning in this cycle.

- For safe rotation, the pallet load is flipped over 180 degrees, the new pallet is placed on top, and it is fastened with forks and side panels.

As the product load is inverted, the old pallet returns to the top, attaching the new pallet at the bottom; alternatively, the product load may be manually rotated 180 degrees, then inverted again by 90 degrees to rest on the platform. This makes room for a fresh pallet to slip in.

- The whole load platform is rotated 180 degrees and then 90 degrees backwards to secure the new pallet between the load and the previous pallet. The fresh pallet load is then removed using the forklift, leaving the first pallet behind.When the initial pallet load is successfully transferred to the new or destination pallet, the cycle is finished. For a visual explanation of the portable pallet inverter’s functioning, see our demo movies.

It is simple to use the portable pallet inverter. Your operator can easily replace up to 20 pallets per hour with little effort if they have received the necessary training.

Pallet handling revolutionised by portable pallet inverters

A portable pallet inverter is a device made to rotate and invert pallets, making it simple to load and unload goods without the need of labor-intensive equipment or physical labour. Its mobility makes it simple to move about a facility, making it a useful tool for manufacturing and warehousing operations.

Worldwide Sales of Over 5,000 Units!

We are happy to report that more than 5,000 portable pallet inverters have been sold internationally. With the help of our cutting-edge technology, several companies have improved productivity and simplified their processes while saving significant amounts of time and money.

Initially Created by Toppy

We are proud to have provided the first portable pallet inverter, which established the benchmark for pallet handling systems. The Toppy portable pallet inverter is built with precise engineering and premium components to guarantee longevity, dependability, and user-friendliness.